No products in the cart.

£8.00

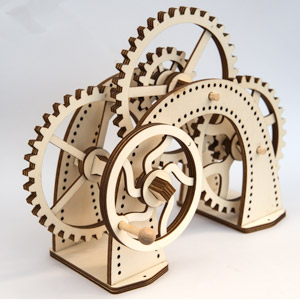

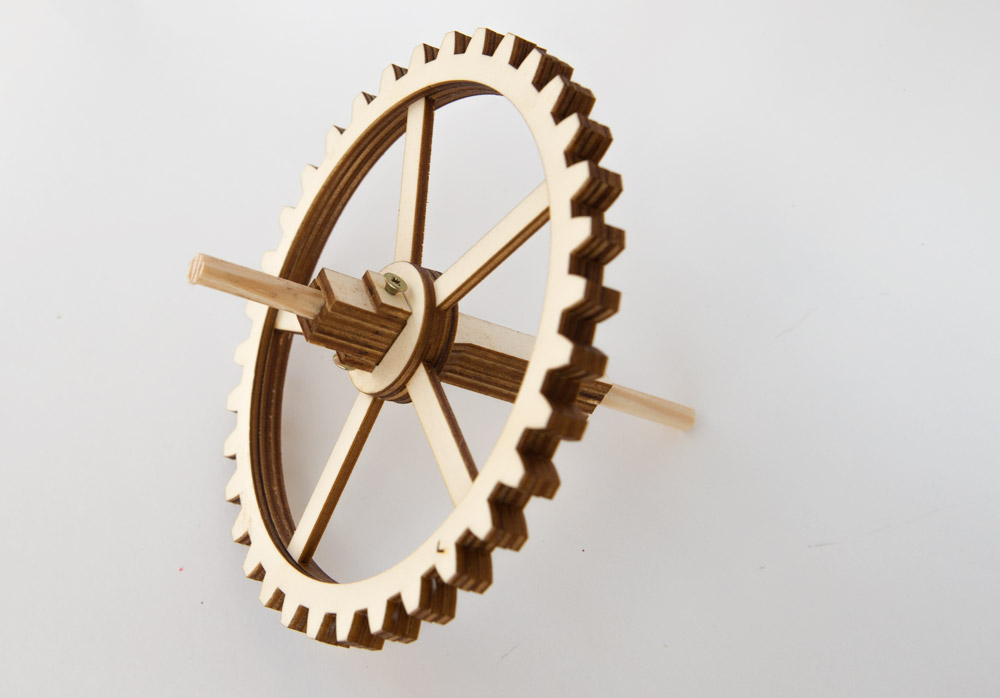

Gear Train : Laser Cut : Download and Make

Download the parts in pdf to cut out on your own Laser-Cutter.

If you don’t have a laser cutter you can often get access to one at a MakerSpace, Hack-Space of Fab Lab – search the web for one near you.

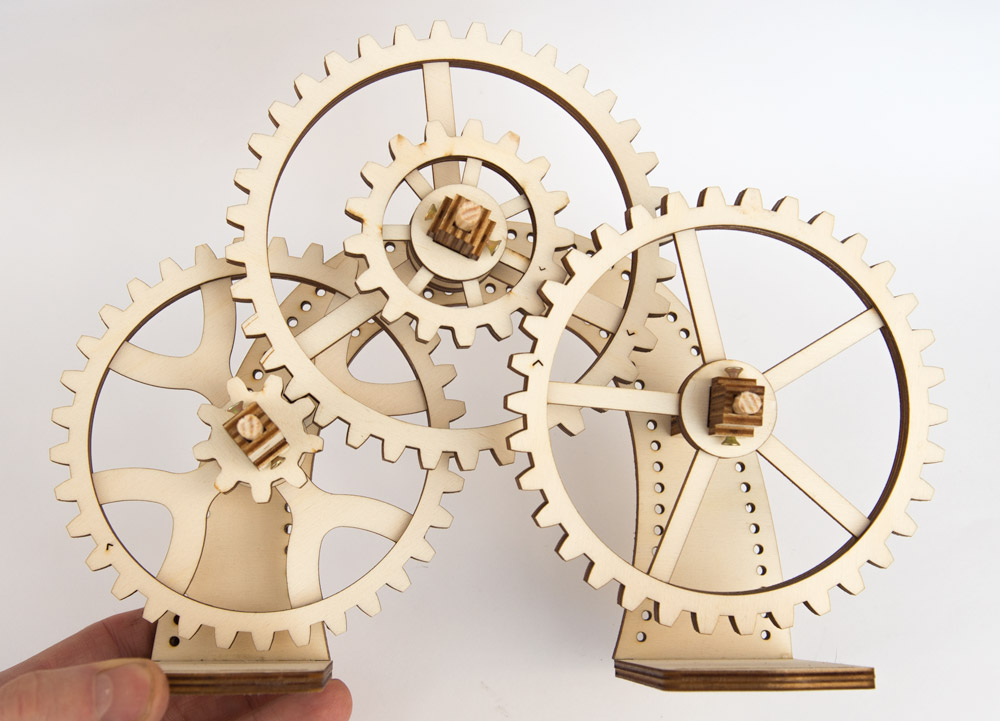

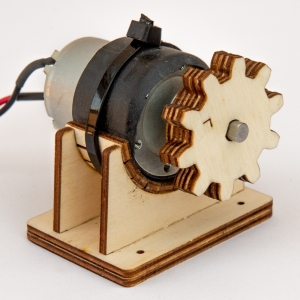

Turn the handle on the gear train and the gears get faster and faster! The final gear turns eight times as fast as the input gear. Once you have downloaded the file, import them into your software of choice and transfer them to your laser cut. I used 3mm thick birch ply for this model. You will also need several pieces of 6mm dowel. 5 of 30mm long and 2 of 50mm long.

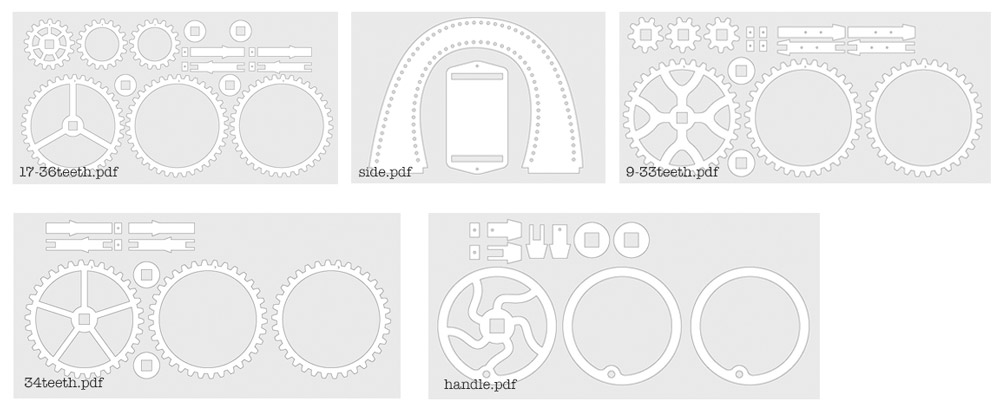

There are five files in the downloadable zip file. One for each part of the project.

We’ll go through each part and assemble them. Once they are all complete we’ll put the whole thing together.

Starting with 17-36teeth.pdf

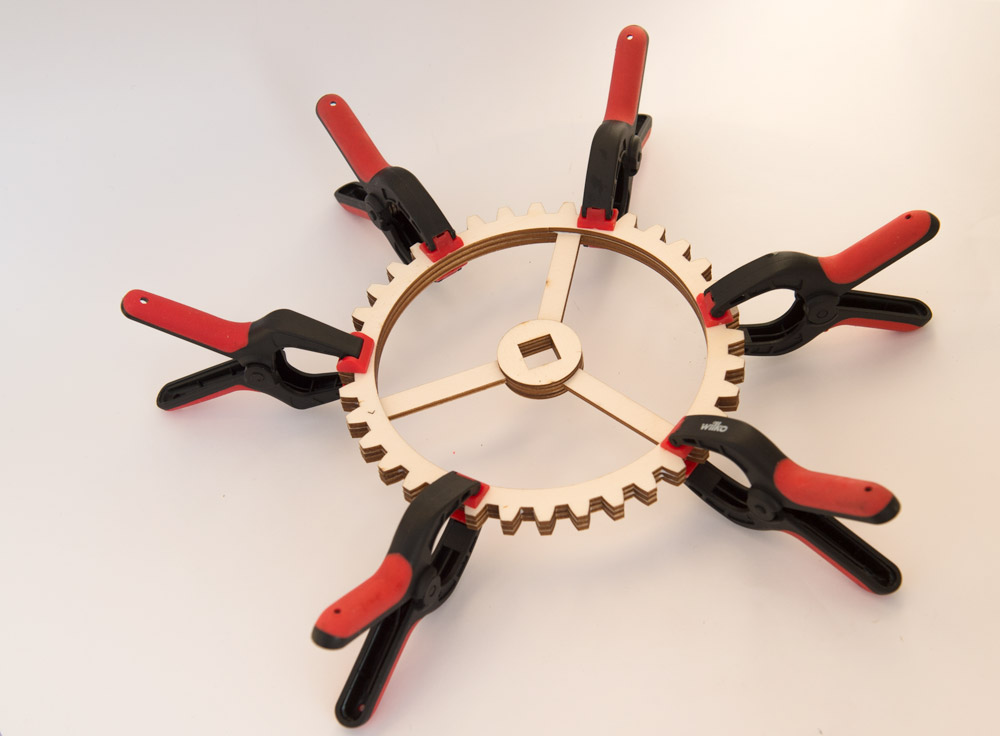

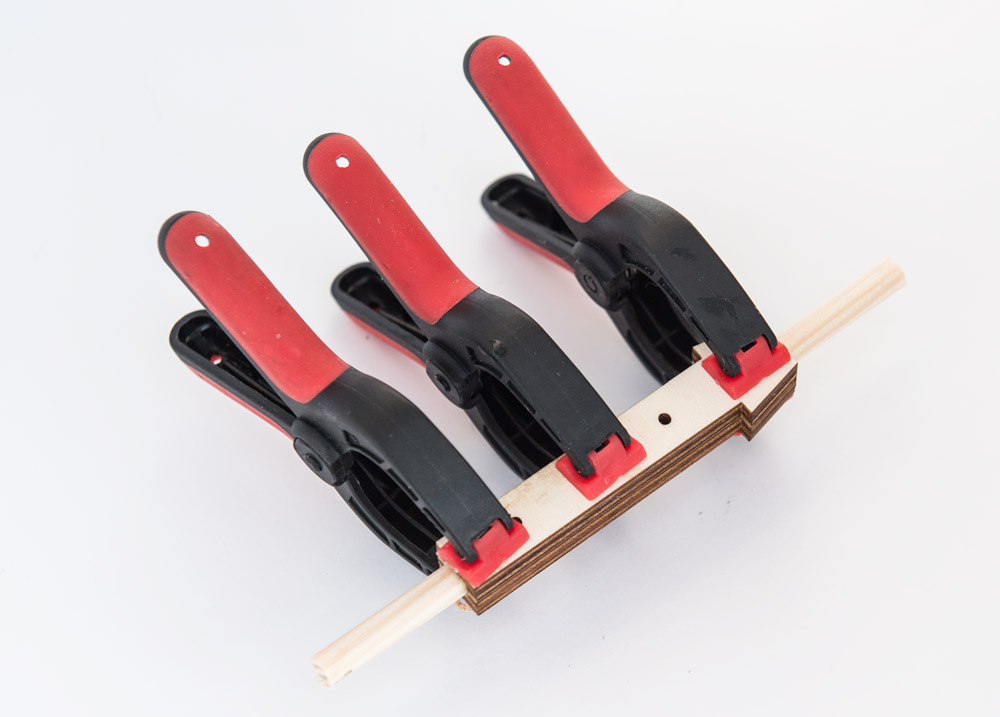

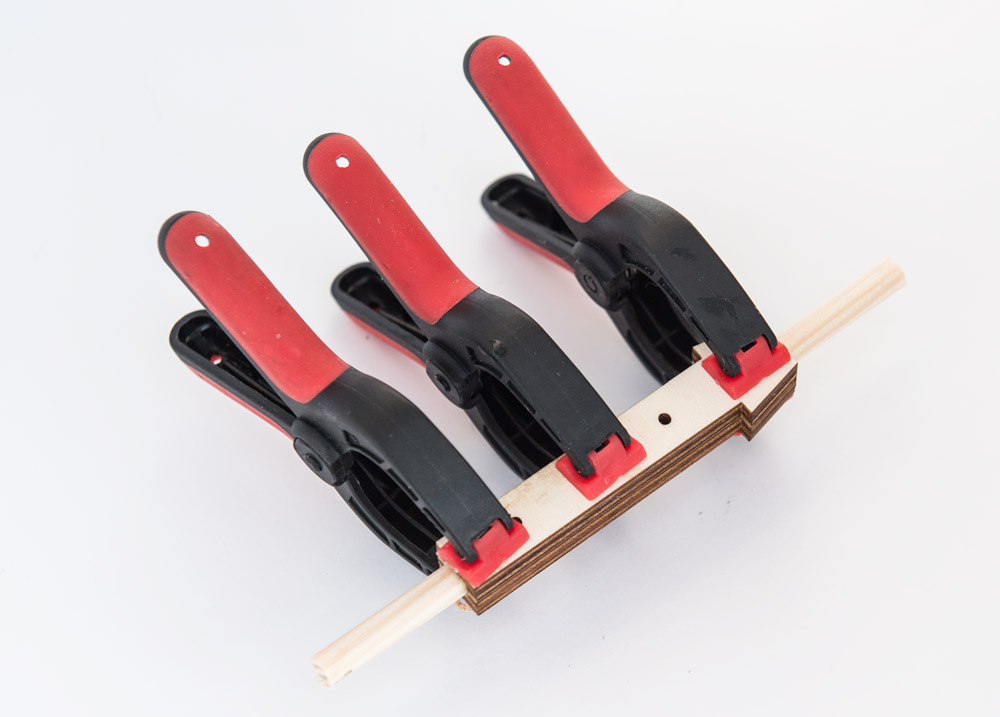

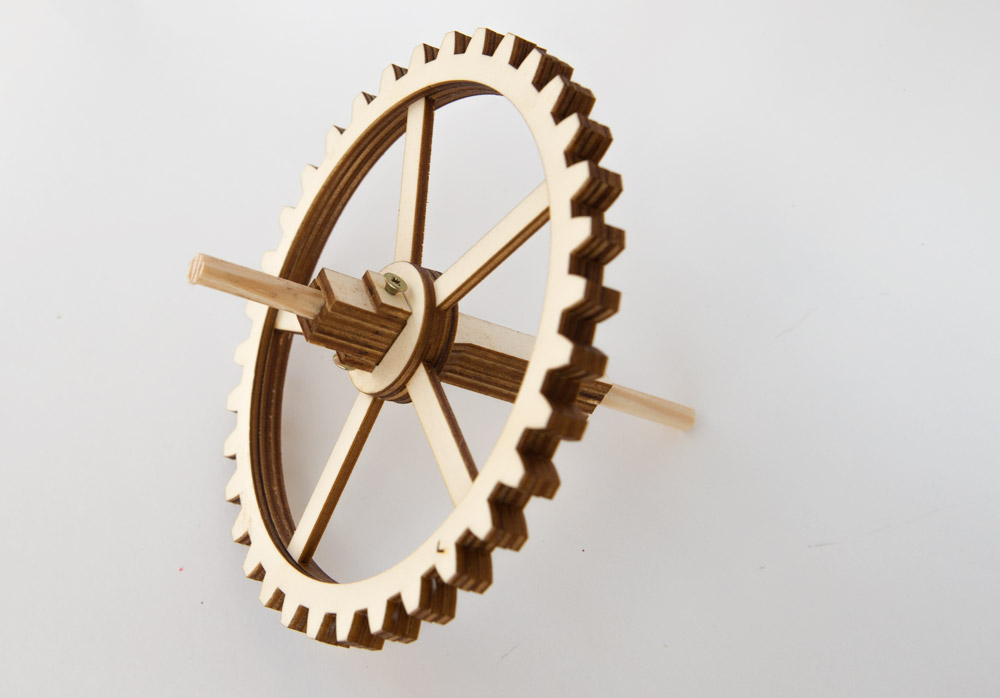

Make up the large gear from three layers and glue/clamp them into place. Make sure that the teeth are lined up accurately!

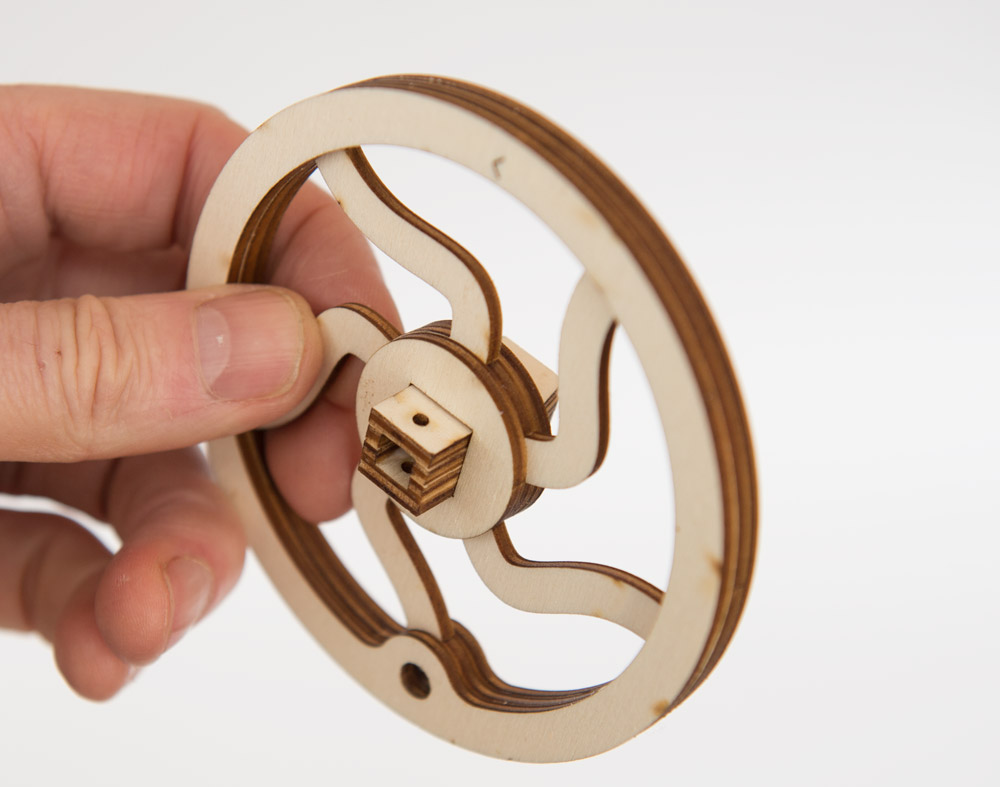

As with all the gears, the small ‘v’ shape helps with alignment and orientation.

Make the smaller 17 tooth gear in the same way.

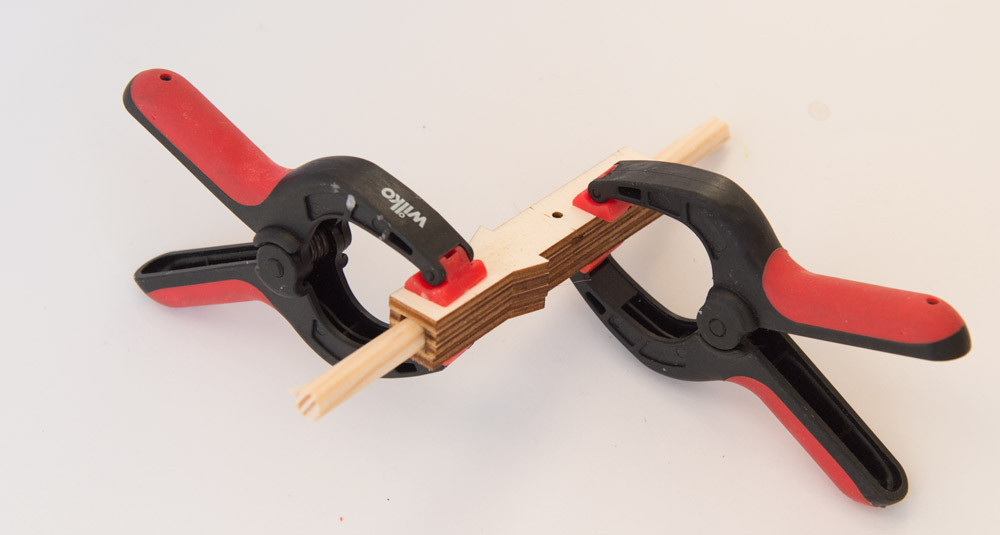

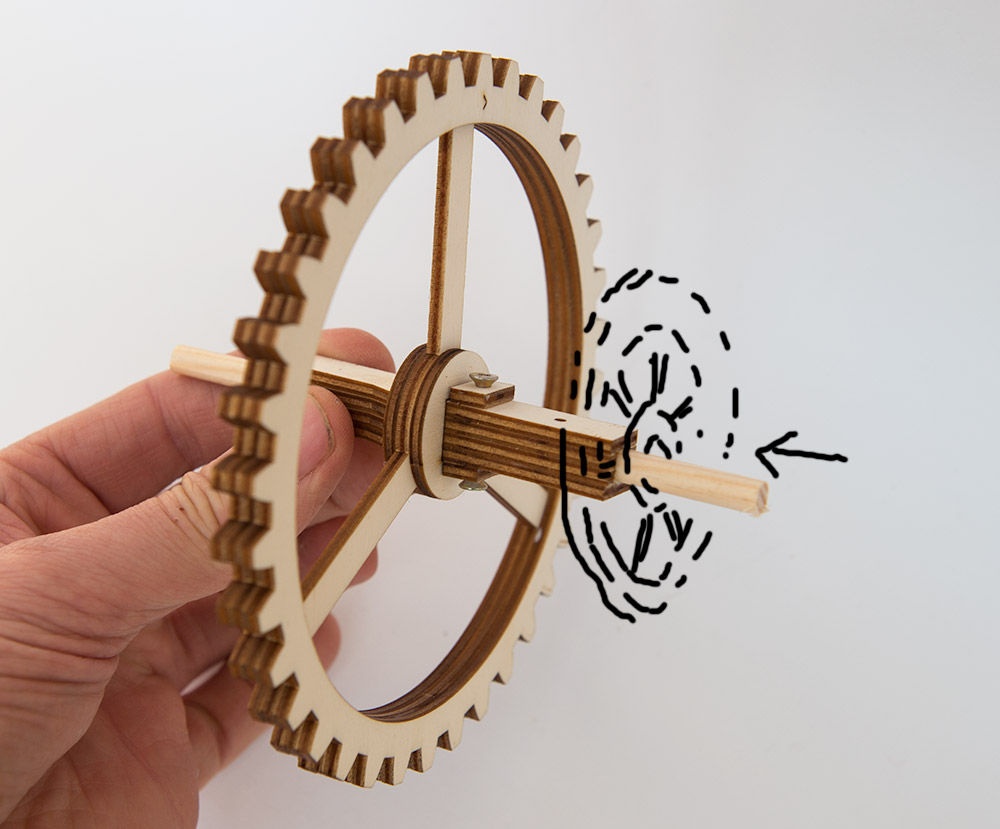

Make the axle from four layers and glue a 30mm long dowel in each end. Make sure all the parts are accurately aligned.

Slide the large gear onto the axle, no need to use glue. Screw one of the small blocks onto each side to locate the gear into position. Slide the second smaller gear into place, again without glue. Secure it into position with another pair of small blocks.

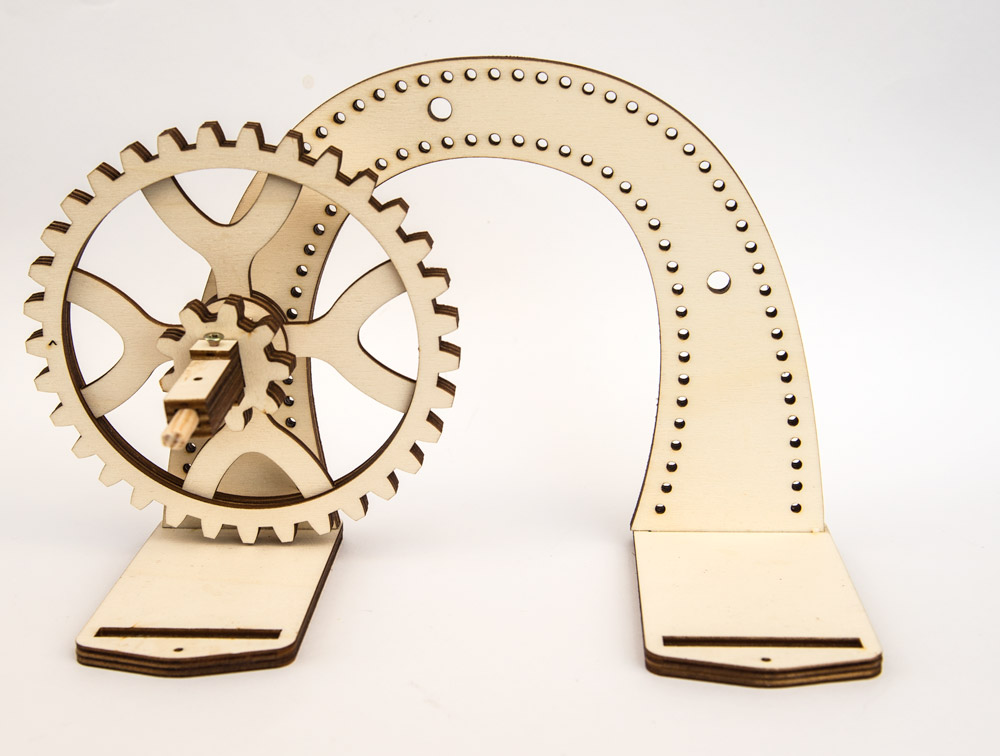

Making side.pdf

You’ll need four copies of the parts on this page.

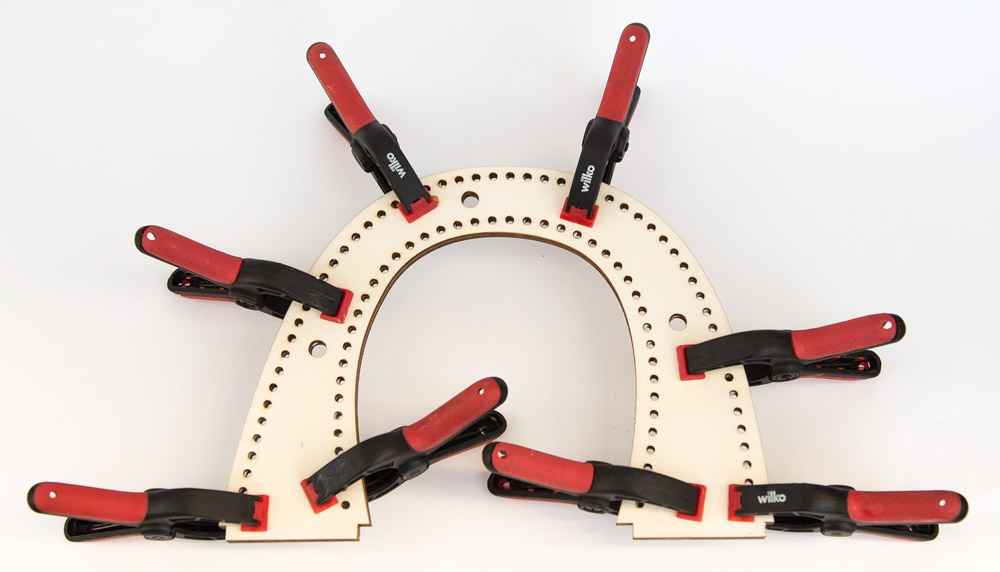

Glue and clamp the arches into two pairs. Glue and clamp the bases into two pairs as well.

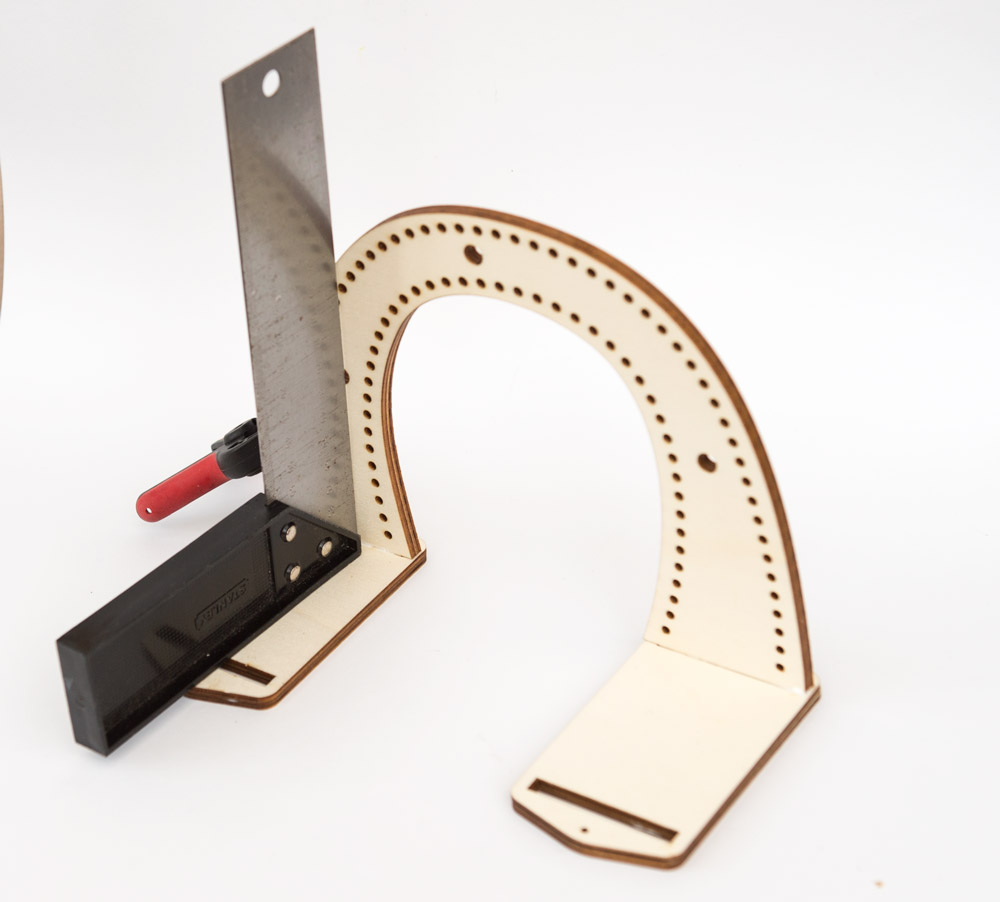

Glue one side to the two bases. Use a set square to make sure the parts are square.

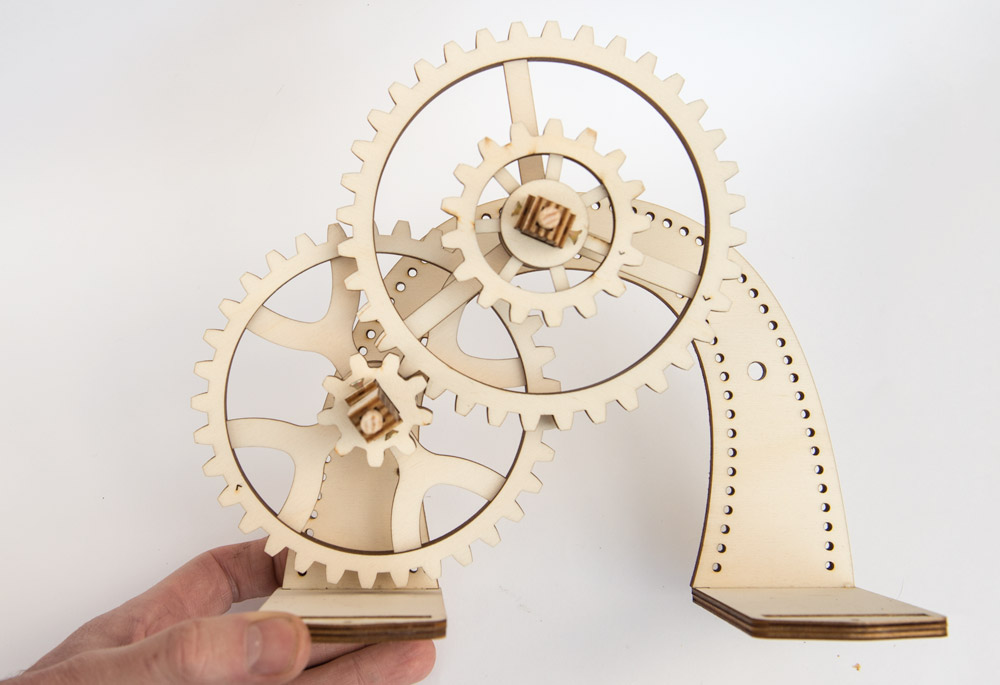

Making the 9-33teeth.pdf parts.

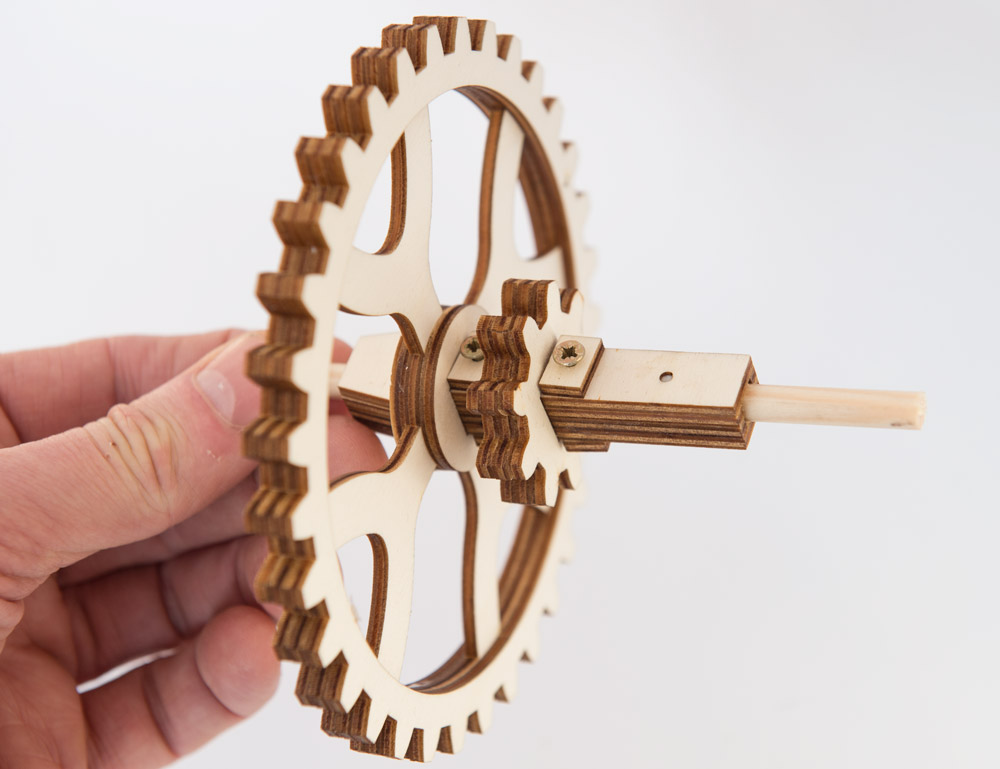

Make the gears from three layers making sure that the teeth are accurately aligned.

Assemble the axle from four layers making sure everything is lined up as accurately as possible. Glue a 30mm long dowel into each end.

Making the parts from 34teeth.pdf

This part has only as single 34 tooth gear fixed to an axle.

Glue and clamp the three layers.

Make up the axle for this gear as before but this time fit a 50mm dowel in the end opposite the gear and a 30mm dowel at the other end. Slip on the gear and secure it with a couple of small blocks and screws.

Making the handle.pdf

Make up the four layers of the short axle stop and slide it into place. No glue needed.

Glue the remaining 50mm dowel into the hole in the handle. If you have one a small wooden ball makes a nice end for the handle.

Final Assembly

Fit the parts together in the order shown.

Finish off the model by fitting the handle to the long dowel on the single gear and fixing it into place with a spacer block and screw.

Rated 5.00 out of 5 based on 1 customer rating