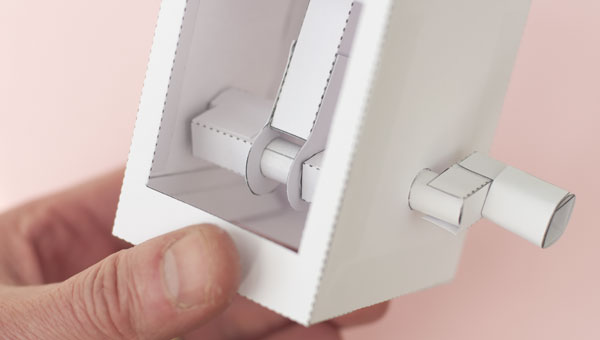

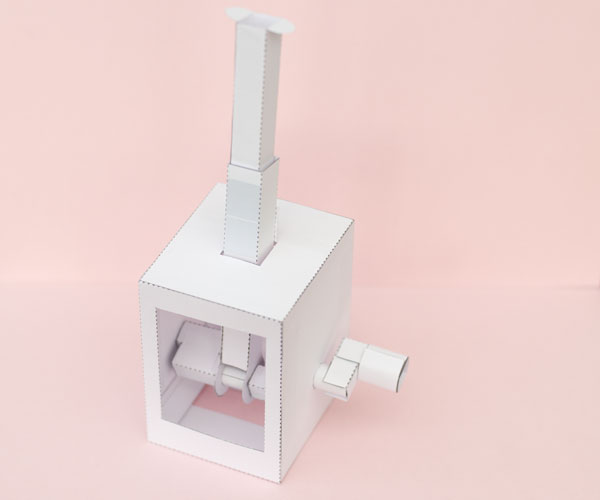

Inspired by the smooth running of the gear bearings I thought I'd have a go at improving the bearings on my basic crank slider mechanism to see how well it would work. Turns out – pretty well!

In the original crank slider mechanism a square shaft fits into a circular. Simple but not very precise. Square shafts are handy because they can be joined together easily. This is because they have nice flat surfaces for gluing.

By gluing a circular tube into the square tube I aim to achieve the best of both works. Accuracy and ease of joining.

A secondary side effect of the switch to circular axles is that the hole through which the axle passes is smaller. In this case 10mm diameter instead of 14mm. This means that the ends of the main push rod and be smaller and neater.

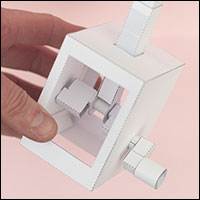

The assembled unit fits nicely into the box.

Turn the handle and the crank turns beautifully smoothly with very little play. A big improvement on the previous design whilst still being easy to make.

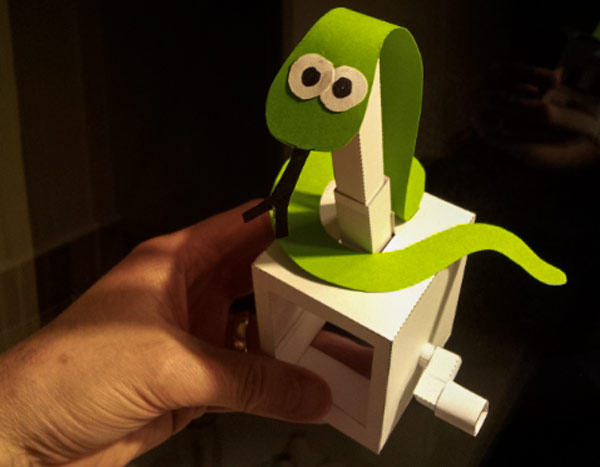

It might make a nice cobra!

I'll put together a download version of the mechanism for members to download tomorrow.

<—- edit —->

It's really nice to have #1 Daughter is back home from uni. She's been watching 'Chalet Girl' with #truelove and I've been cutting and sticking. I made this snake prototype 🙂