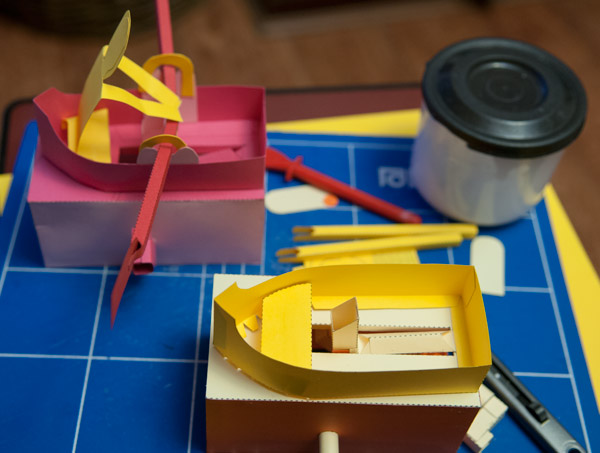

Starting from my finished prototype I’ve followed my usual process of measuring up the parts and transferring them to the computer before printing out the bits and making up a final uncoloured model.

The trouble is I’ve done something wrong somewhere and I can’t see where! The push-rod that drives the oar just doesn’t go where it should go, ending up in the final quarter of the crank turn almost flat to the box top. There are four key measurements and either I’ve not measured them accurately or they are incredibly sensitive to error. Either way it’s really frustrating and I’m calling it a night.

Pah. Wish me better luck for tomorrow.