Experience has shown that connecting acrylic gears to acrylic shafts is tricky. Up until now I’ve been cutting holes in the acrylic with the laser cutter and push fitting the gear onto the shaft. For a 6mm shaft I’ve cut a hole between 5.7mm and 5.8mm. Sometimes it works, and is a nice tight fit, other times the gear cracks as it is pushed into place.

My first attempt as designing a sprung connector failed when three of the five fingers snapped off at the first attempt.

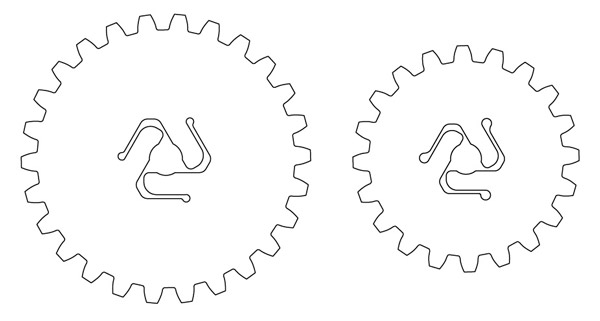

My second design is simpler and hopefully more robust. I’ve added curves to all the corners to spread the strain.

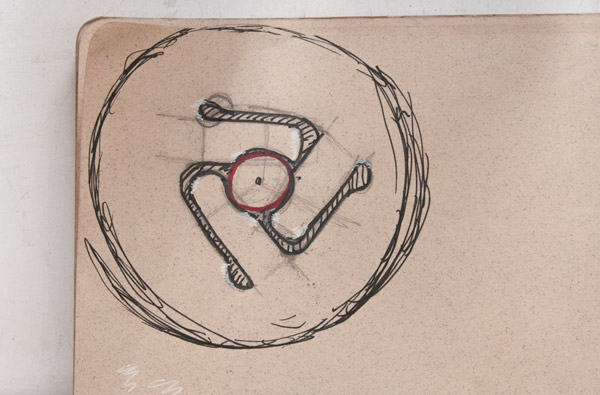

Here are the first and second drafts for the gear centre design. in each, the central circle is 5.7mm in diameter. The spring of the three fingers allows a 6mm shaft to ft into place and grips it tightly.

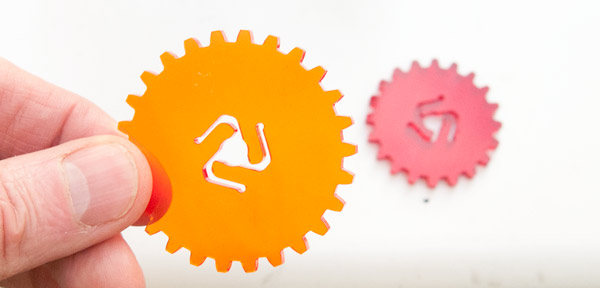

Here are the final gears cut out and ready to go.

They work nicely, gripping the shaft and holding the gear square.