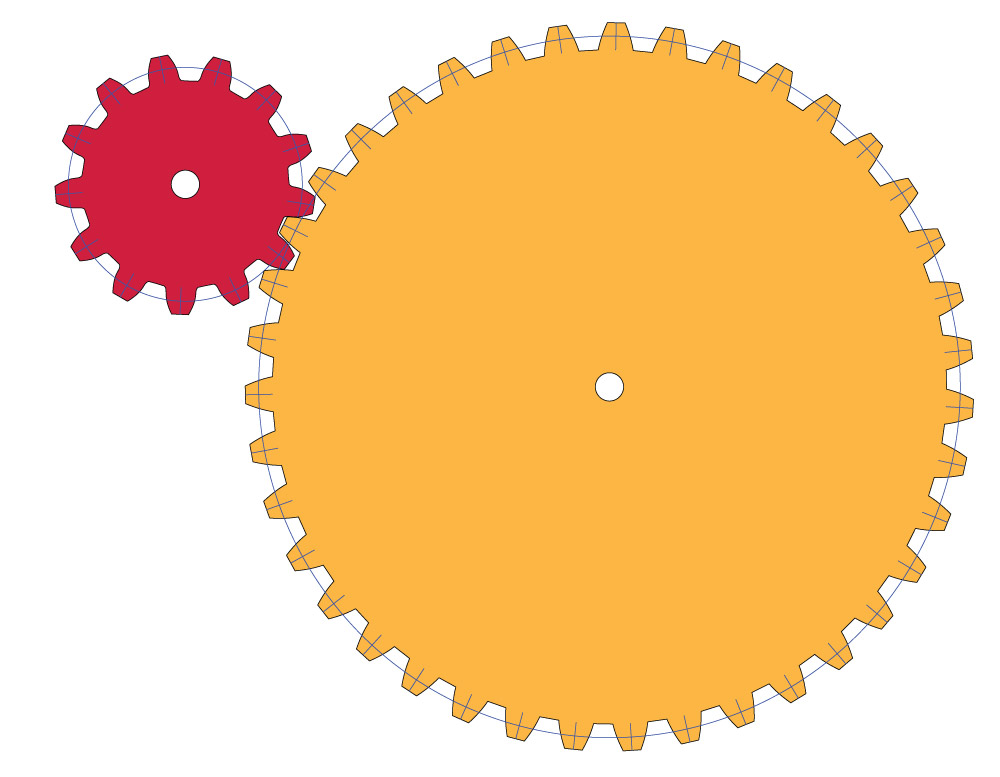

As part of a forthcoming laser-cut project I need a 3:1 gear reduction. It is a fairly small reduction which could easily be made with just two gears. For example… This gear pairing is a 13:39 which would reduce the output speed of the orange gear to one third of the smaller pinion gear.

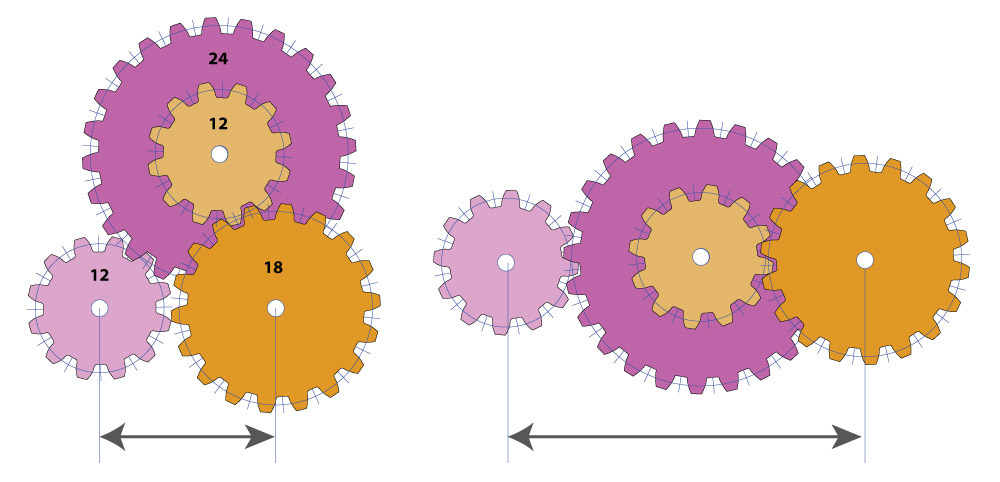

The difficulty I have with this layout is that the distance between the two gears is fixed, based only on the pitch of the gear teeth. By adding a send step and making a compound gear it will be possible to change the distance between the input gear and the output gear without varying the size of the gear teeth.

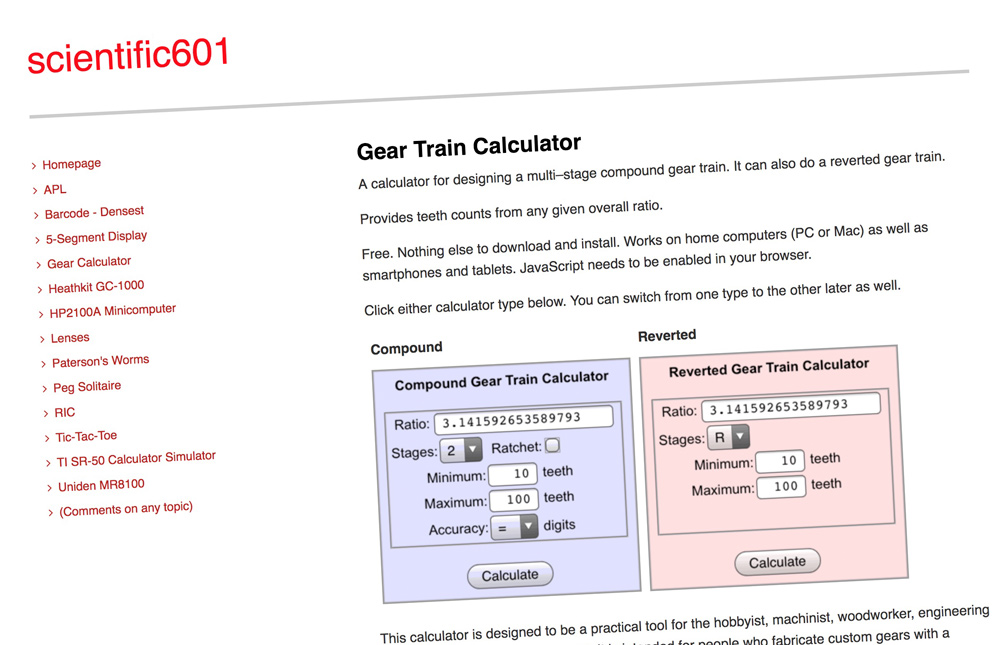

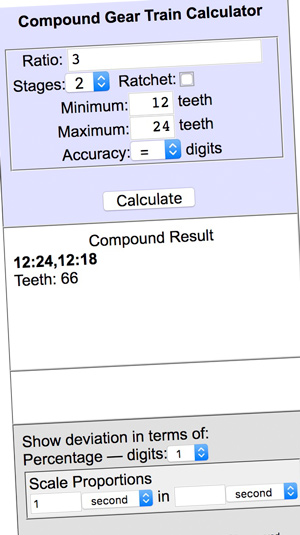

I found a handy tool online to help with choosing gear ratios…

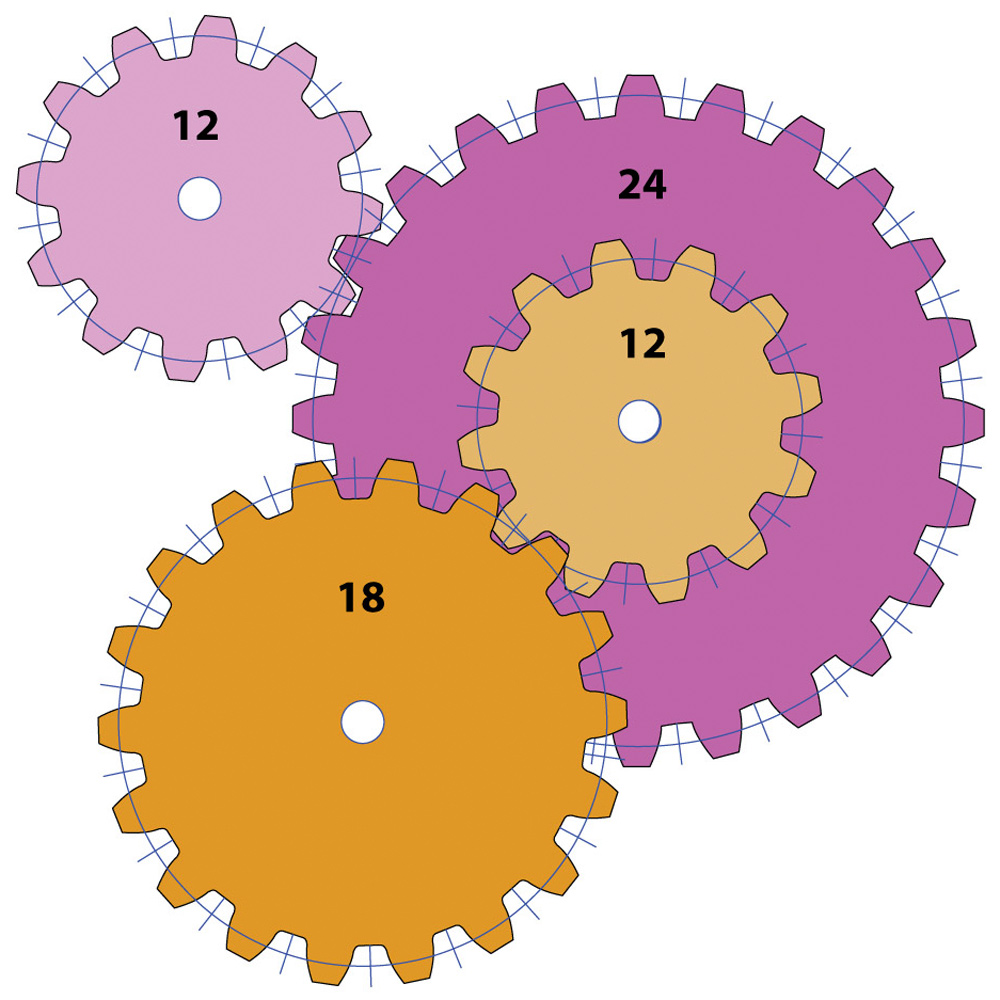

I entered a minimum and a maximum number of teeth and hit calculate. The suggested result was these two gear pairs 12:24 and 12:18

I entered a minimum and a maximum number of teeth and hit calculate. The suggested result was these two gear pairs 12:24 and 12:18

[clearboth]

The output from the final 18 tooth gear is one-third of the speed of the input 12 tooth. By splitting the drive into a compound gear the distance between the input and output can be easily changed by varying the angles between the gears. Next step will be to add a Geneva drive into the design.