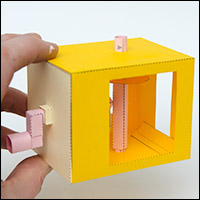

The intermittent drive shaft on this mechanism rotates quarter of a turn for each turn of the handle on the side of the box.

The intermittent drive shaft on this mechanism rotates quarter of a turn for each turn of the handle on the side of the box.

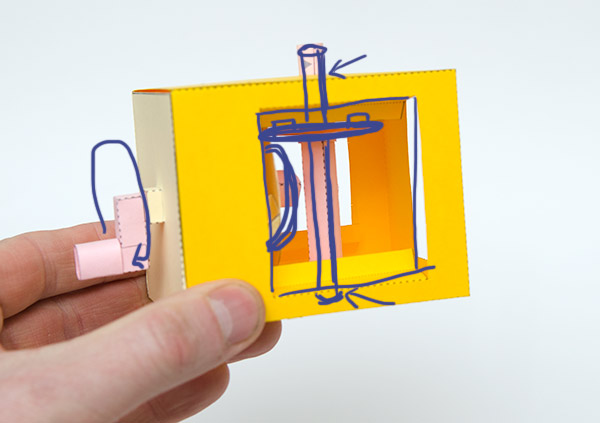

There is a disk at the bottom of the vertical shaft that is driven round by the cam on the horizontal shaft using friction. The friction is low between the two parts so the vertical shaft has to be a loose fit. The problem is that as it is a loose fit it moves easily from side to side just as the animation shows.

Imagine that the whole mechansism is rotated onto its side. The vertical shaft could still be a loose fit but because of the increased length there would be far less movement side to side. The horizontal shaft is a tight fit in the holes so it is not be prone to side to side moevement in the same way.

There are two or three ways I can lay out the parts with the vertical shaft running the full height. Time for some more prototypes