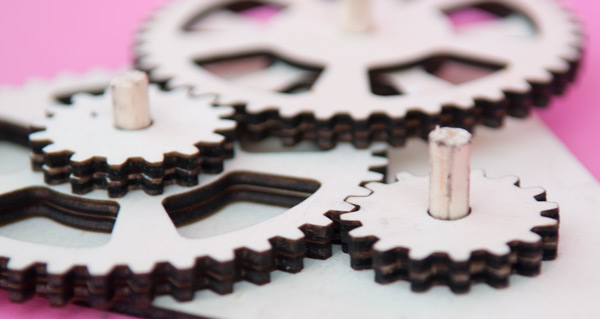

More experiments with laser cut gears. This gear train uses two of each of sixteen tooth and forty two tooth gears each designed using the unmatchable Gear Template Generator The first results look promising fitted to a board with suitable six millimeter dowel axles. There is, however, a definite gap where the teeth mesh.

The problem is clear to see in this animated gif. The teeth should mesh precisely without this movement. In the original design on Gear Template Generator there is no gapping between the teeth.

The problem is clear to see in this animated gif. The teeth should mesh precisely without this movement. In the original design on Gear Template Generator there is no gapping between the teeth.

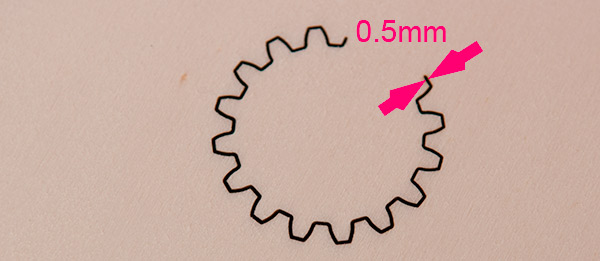

Here is where the problem lies. This picture shows an almost completely cut gear. (It was abandoned because I’d started cutting the outline before I cut the axle hole. The smaller holes need to be cut out first because the piece tends to move slightly once it is cut free of the board, subsequent cuts are then mis-aligned) This waste piece gave me the chance to measure the width of the cut with my calipers. I make it just half a millimeter wide.

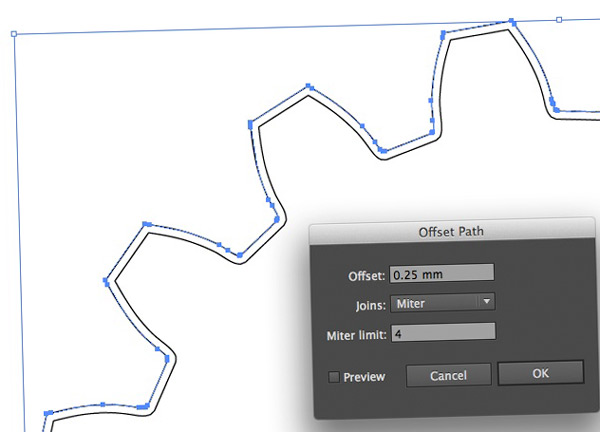

In Illustrator I used the ‘Offset Path’ tool to add an extra quarter millimeter to the profile of the gears, half the width of the cut line.

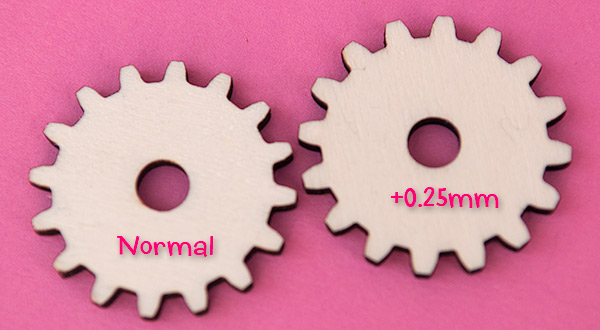

The newly cut gear certainly looks more balanced. The gaps between the teeth looks closer in size to the teeth themselves.

Here it is assembled. The teeth gears mesh very nicely and run smoothly with very little play in the movement.

Next: Which work best? Single or double thickness gears.