I'm working on a ratchet model for the mechanisms section, it is proving less straightforward than I thought it would be!

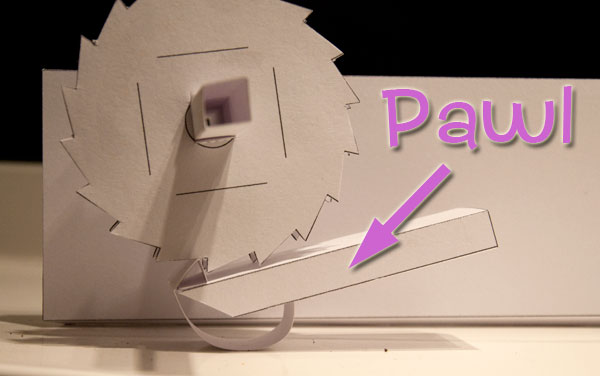

There are a couple of ways that a ratchet can be used. Either the pawl is used to let the main wheel from rotate only in one direction, think of a winch lifting a bucket out of a well. In the picture above the wheel will only turn counter-clockwise. Let go of the wheel and bucket won't fall down the well.

That said, I'm going for the other use of the ratchet. In the counting sheep model the ratchet is used to advance the count wheel one step at a time. I wanting to do something similar where the ratchet pawl is attached to a crank. Turn the crank and the ratchet wheel advances on tooth at a time.

That said, I'm going for the other use of the ratchet. In the counting sheep model the ratchet is used to advance the count wheel one step at a time. I wanting to do something similar where the ratchet pawl is attached to a crank. Turn the crank and the ratchet wheel advances on tooth at a time.

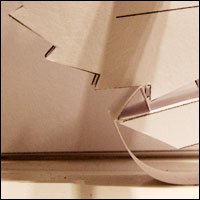

So, problems: the counting sheep model works fine but if you turn the crank the wrong way the pawl lifts off the wheel. If it stayed on the wheel then you would be able to turn the crank in either direction and the wheel would always advance one tooth at a time in one direction. Today's attempt I tried putting the model together with the pawl at the bottom rather than the top of the wheel. The curve of card (top picture) works as a leaf spring holding the pawl against the wheel.

The problem then is that there is friction between the pawl and the wheel. As the pawl moves it drags the wheel with it. The result is that the wheel just moves back and forth, no ratcheting goes on!

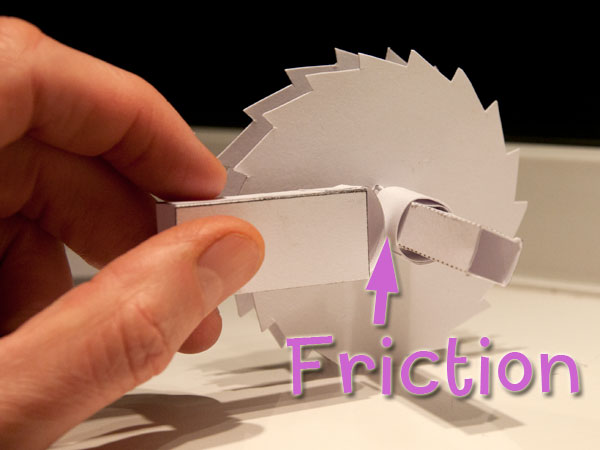

To stop this happening I need a certain amount of friction on the main wheel axle. I could have a tight fitting axle, the trouble with that is that over time the axle hole will wear and the friction will reduce. Eventually the ratchet will stop working. Today's attempted solution, still on the leaf spring theme, I'm trying a spring pressed up against the axle. Once I've posted this I going put all the bits together and see how it goes. I'll be reporting back tomorrow.